The Dies and Tools Division designs and manufactures dies and tools of any size and any kind, such as:

1. Manual Dies

2. Transfer Dies

3. Progressive Dies

4. Programmable Dies

5. Dies for drawing, deep drawing, stamping, bending, cutting, trimming, notching, piercing, clinching, seaming and so on

6. Dies to process any kind of sheet metal as carbon steel, steel to be enamelled, galvanized, stainless steel, aluminum, pre-painted, pre-coated, co-laminated sheet, etc.

The Dies & Tools Division works for all sectors requiring sheet metal stamped parts, such as Home Appliances, Automotive, Heating and Air-Conditioning, Sinks, Bath Tubs and Shower Stalls, Buildings, Textile, Energy, Lighting, Fluid Treatments, Internal Fittings, Ecology, I.T. and many others.

Extensive in-house capabilities as 3D CAD, CAM and CAE stations, EDM, CNC machine tools also high speed and 5 axis, CMM for quality and capability tests, all connected by network, hydraulic and mechanical try-out presses, cranes up to 30 tons, allow to deliver top quality tooling to the best customer satisfaction.

Dies Project Developement

CME on his RND Dept. is always study and develop new solutions to get benefit for customers’ needs and cost optimization grant the highest quality of products and DIES. CM EVolution is willing also the prototype phase making forming analysis and by a soft tools produce a batch of samples for the customer DC ( design confirmation ) purpose sharing all possible variables , changes, modifications that need to be done in the design project to finalize the product.

Dies Machining

The Company capacity is very high, with numerous 2D and 3D CAD, CAM and CAE working stations, any type of CNC machine tools, high speed milling machines, grinding machines, lathes, 3D CMM machines.

High Speed CNC Machine

CNC FidiaC1, Parpas SL100 (new CNC 01/2014), FPT VERUS VM 0608033, CNC Heidenhein 530, SIGMA LEADER 6 L6072, CNC Heidenhein 530, SIGMA LEADER 7 7086, CNC Heidenhein 530, SACHMAN MOD. T 20 (CNC FIDIA) F1, CNC FidiaF1, AMCA GANTRY, CNC Fidia F.

Dies Assembly

Assembly dies of any dimension and type such as manual, transfer, progressive and programmable dies, dies for the drawing, and so on. The Dies’ assembly area works for all sectors that have products with sheet metal components such as white goods, automotive, heating and air-conditioning, sinks and sanitary and many more.

DIES PRESS

Mechanical and hydraulic presses. Hydraulic Press Muller 800, 3200 x 2000 x MAX shut height 1920mm with lower hydraulic cushion 200T; ram stroke 900mm; moving bolster, Mechanical Press Weingarten VK600.32 600T 3000 x 1800 x MAX shut height 2200mm with upper/lower pneumatic cushion; ram stroke 700mm, ram setting 400mm; moving bolster. Spotting Press Cavenaghi Ridolfi 2000 x 1500 x max shut height 2000

CMM

The CMM department has two machines:1 automatic and 1 manual where all the parts will be controlled and pass thru FPA, capability Study complete analyses of product and also for parts quality dimensional report.

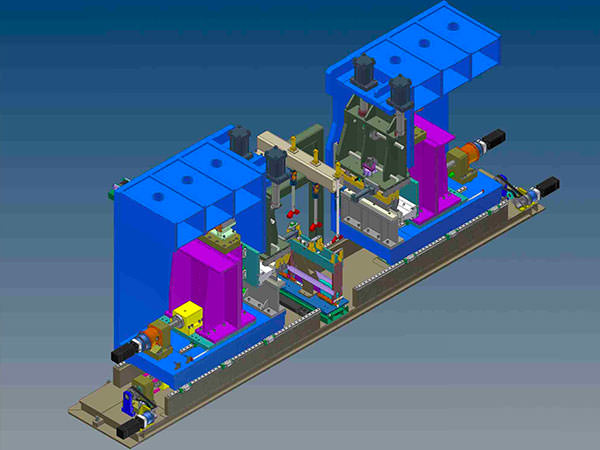

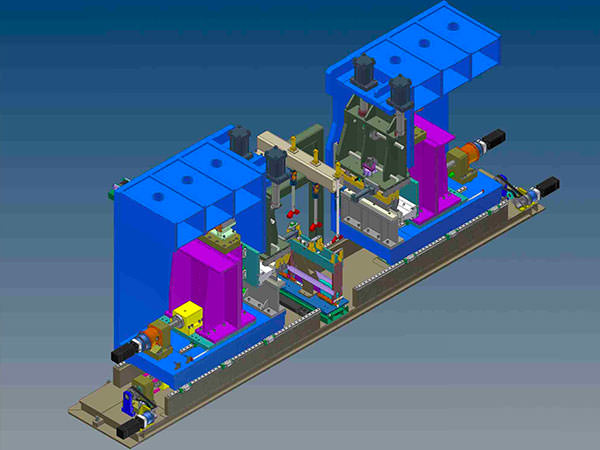

Systems

System division designs and manufactures special machines and lines for the processing and the assembly of the sheet metal, including presses and stamping dies lines, as well as fully integrated and automated systems.

Lines Assembly for washing machine and dryer drums, basket, tubs, cabinets and frontal panels of washing machines and dryers, dishwashers, doors, cabinets and chassis of refrigerators and, freezers, kitchen ovens, cookers, cabinets and chassis of air conditioners, as well as subgroups of vehicles, electrical boxes, cabinets and metal shelving, doors and metal panels for building facades, etc.

Panel Assembly Line

Fully automatic panel assembly line for appliance products.

Wash Drum Assembly Line

Automatic line for drum washer manufacturing and assembly.

CNC Bending Line

Special cnc bending machine for different applications and different products.

Washer Cabinet Assembly Line

Special cabinet assembly line with clinching assembly process.

Panel Welding Line

Fully automatic welding line for assembly of different parts of Washer cabinet.

Process

All equipments/machine before their realization are verified with special program for FEA.

System division designs and manufactures special machines and lines for the processing and the assembly of the sheet metal, including presses and stamping dies lines, as well as fully integrated and automated systems.

Lines Assembly for washing machine and dryer drums, basket, tubs, cabinets and frontal panels of washing machines and dryers, dishwashers, doors, cabinets and chassis of refrigerators and, freezers, kitchen ovens, cookers, cabinets and chassis of air conditioners, as well as subgroups of vehicles, electrical boxes, cabinets and metal shelving, doors and metal panels for building facades, etc.

Panel Assembly Line

Fully automatic panel assembly line for appliance products.

Wash Drum Assembly Line

Automatic line for drum washer manufacturing and assembly.

CNC Bending Line

Special cnc bending machine for different applications and different products.

Washer Cabinet Assembly Line

Special cabinet assembly line with clinching assembly process.

Panel Welding Line

Fully automatic welding line for assembly of different parts of Washer cabinet.

Process

All equipments/machine before their realization are verified with special program for FEA.